Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

Vmadelaser : Best Fiber Laser Cutter for Sale | Fiber Laser .

Fiber laser machines allow you to safely cut a range of metal materials with high speed and accuracy.

Find the Right Laser Cutting Machine Manufacturer in China. High Quality Laser Cutting Machine with Competitive Price.

Optional: :Semi-Automatic loading system

Optional: :Fully Automatic loading system

(Simplified workflow saves labor and is more productive)

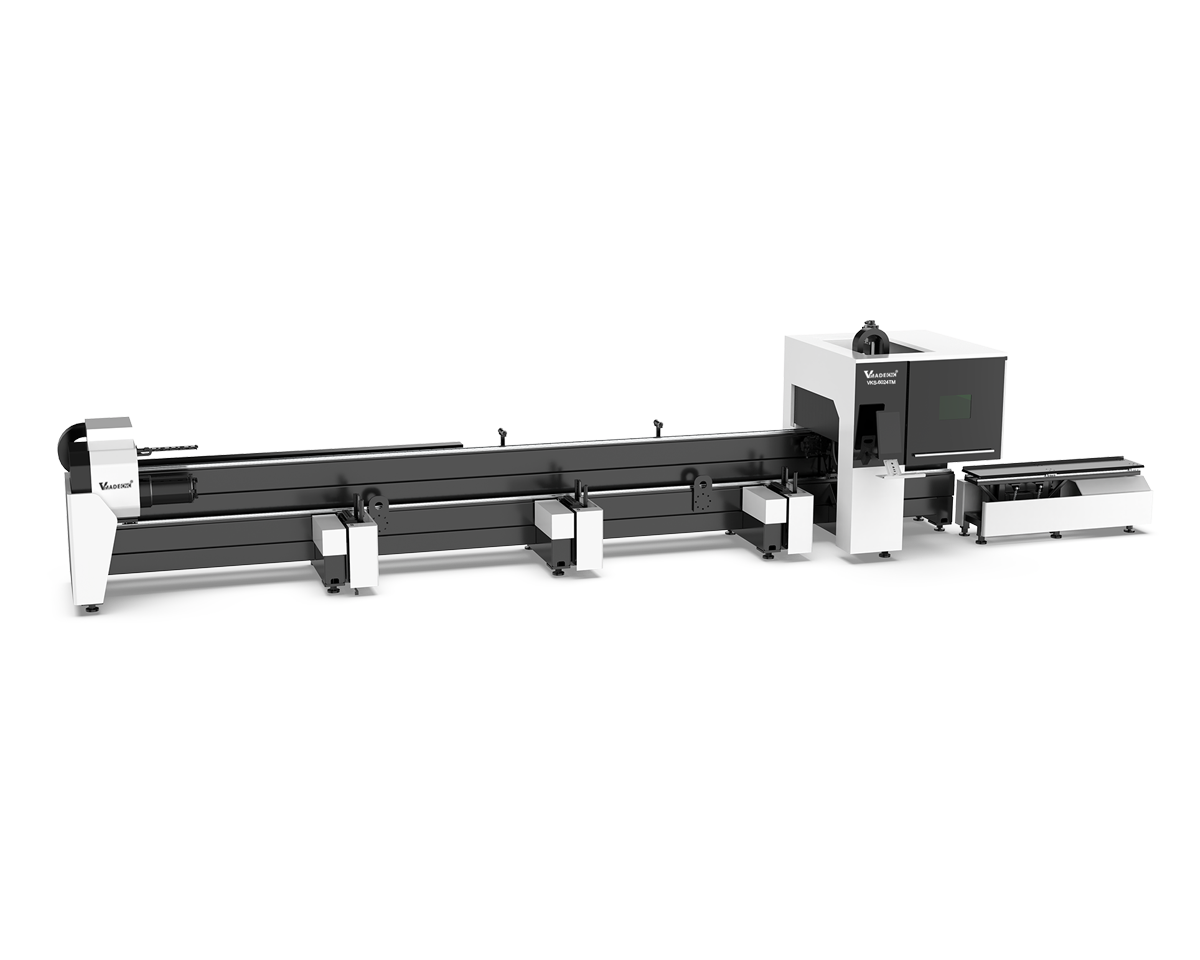

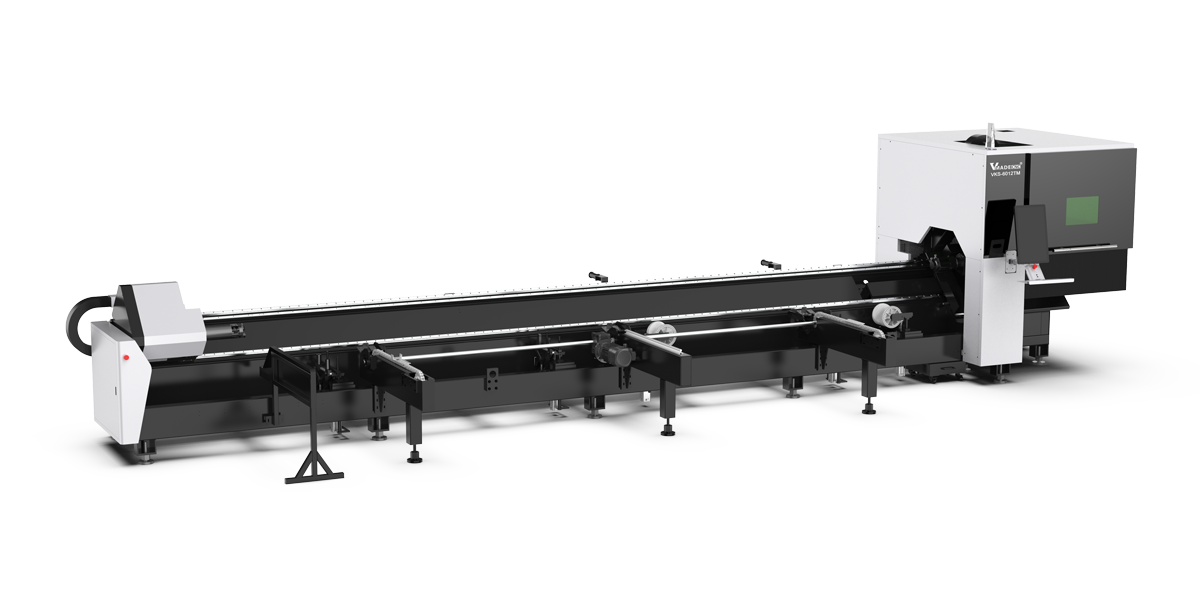

About Ultra High-Speed Pipe Laser Cutting

Ultra High-Speed Pipe Laser Cutting Machine is manufactured by VMADE CNC according to international export standard. This series of equipment is the preferred model for the metal tube processing industry.

Main Features:

1.Stable, lightweight structure with high dynamic responsiveness;

2.Semi-automatic chain-type loading system included as standard;

3.Pneumatic chuck retraction (secondary Y-axis) included as standard;

4.Unloading platform optional (up to 3500mm, with dual adjustable-diameter support wheels).

For more product information, please view our product list.

If you are interested in our products, please contact us now, We will give you the best price!!

Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Front card offside,material saving and reliable

Front card offside, front and rear cards work together to

achieve two chucks cutting short tail material

The last cut double card clamping cutting is more stable

The shortest tail material is 30mm.

The side-mounted bed isstable and convenient

The center of gravity of the bed is lowered, and the structure is stable.

Loading and unloading are more convenient, and operation and maintenance are more convenient.

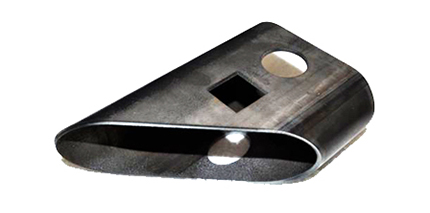

Square chuck, wider cutting range

Adopting square precision pneumatic chuck, the maximum square tube side length is equal

to the maximum round tube diameter, which is suitable for a wider processing range.

Technical Parameters

Project name | Parameter |

Maximum cut pipe length | 0~6400mm |

Cut pipe diameter | 10~80mm |

Minimum tailings | 50mm |

Feeding range | 30mm≤Circumscribed circle diameter≤150mm |

X, Y axis positioning accuracy | ±0.05/1000mm |

X, Y axis repeated positioning | ±0.03/1000mm |

acceleration | 1.5G m/s² |

maximum operating speed | 100m/min |

Chuck maximum speed | 150rpm |

chuck weight | Front and rear chucks each 120Kg |

Installed weight | 6500kg |

Mainframe shape (length, width and height) | About 10700×3700×2410mm |

Application Industry

The action materials include carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized pipe, brewing pipe, aluminum-zinc-plated pipe, brass, copper and other metal materials.

Widely used in furniture, medical machinery, fitness equipment, oil pipelines, exhibition equipment, construction machinery, bus manufacturing, locomotive manufacturing, agriculture and forestry machinery, bridges, ships, household appliances manufacturing and other industries.

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone