Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

Vmadelaser : Best Fiber Laser Cutter for Sale | Fiber Laser .

Fiber laser machines allow you to safely cut a range of metal materials with high speed and accuracy.

Find the Right Laser Cutting Machine Manufacturer in China. High Quality Laser Cutting Machine with Competitive Price.

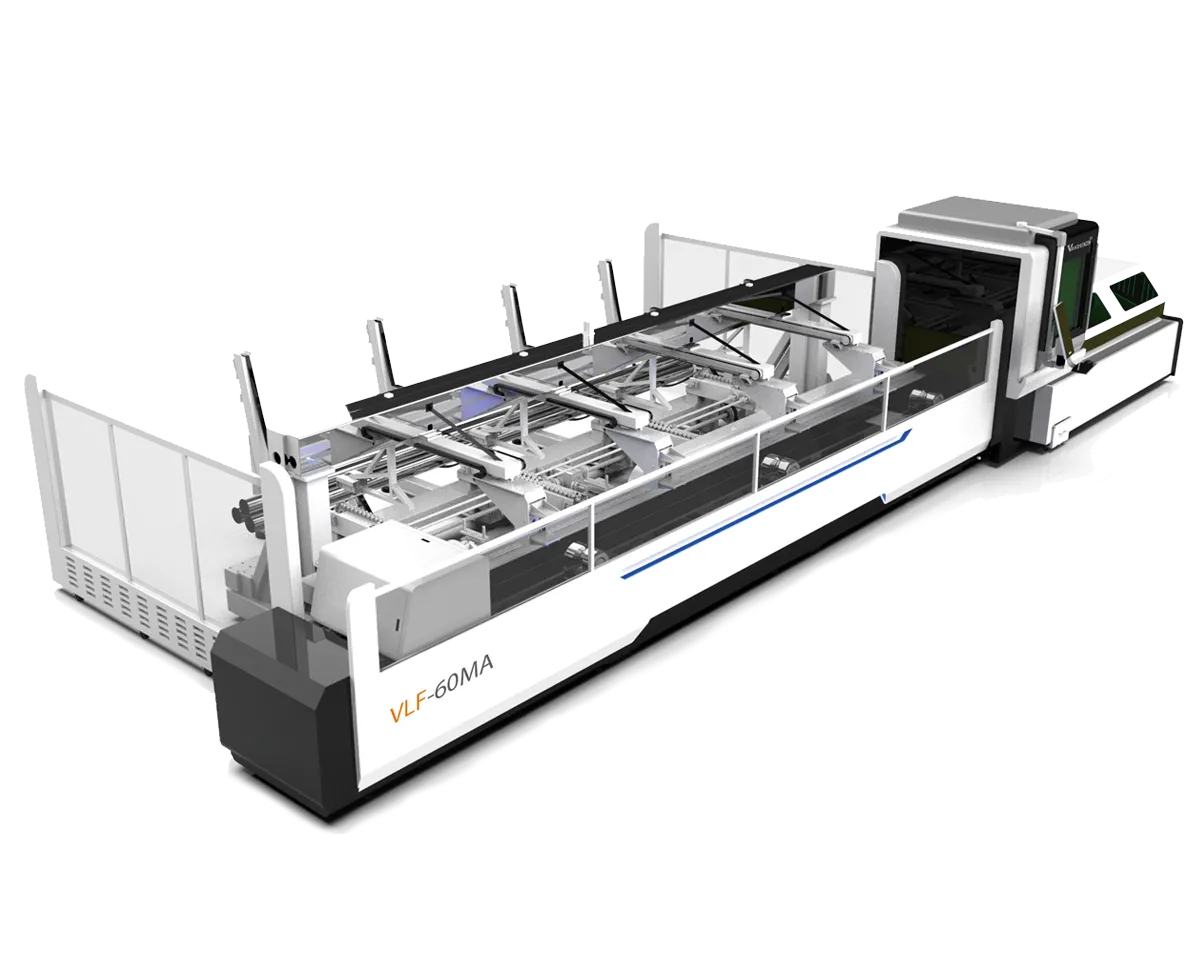

VLF-60MA Fiber Laser Tube Cutting Machine Configurations advantage

1.Moved crossbeam with imported high precision racks and linear guide rail, transmission stable, working with high precision.

Main Features of Auto Loading and Unloading Fiber Laser Tube Cutting Machine:

1.Adopt heavy duty structure,CNC machinery center processing and forming,high strength and good stability;

2.More stronger cast iron stand to keep the machine working more stable;

3.Configure with high accuracy THK linear rail,high accuracy helical gear rack transmitting,more stability,higher precision;

4.Restart from power off,auto feeding,restoration,continue processing at break point.Support 9 coordinate setting,user friendly design;

If you are interested in our products, please contact us now!

Auto Focus Laser Cutting Head

-Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

-Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

-Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Clamp Design

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformationproblems in the process of long tube cutting.

Full-automatic feeding and unloading material device

-Automatic Feeding

Realize the intelligent material separation, feeding and seamless docking with the fiber laser cutting machine after the whole bundles of tubes are placed in the feeding device, and ensure that only one tube is delivered to the conveying arm each time.

-Automatic Unloading

The finished product is automatically dropped to the storage bin, double support-bearing auxiliary support overlong tubes.

Wireless Controller

It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation.

Automatic Stroke Protection

Detect whole process of cutting head working, quickly feedback the risk and stop it. Double protection with fixed limit to improve equipment and personal safety and reduce risk

Intelligent Alarm System

It can detect anomalies in advance, reduce hidden dangers, and double the effect of abnormal detection of equipment.

Technical Parameters

Machine model | VLF60MA |

Laser power | 1000W/2000W/3000W/4000W/6000W/8000W( Optional) |

Dimensions | 12695*5345*2627mm |

Machining range | Hold diameter: Φ15mm-Φ300mm |

Repeated positioning accuracy | ±0.02mm |

Specified voltage and frequency | 380V 50Hz/60Hz |

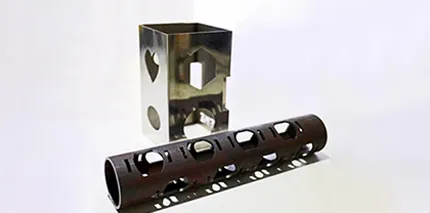

Application Industry

Take the oil industry for example, the main route of oil transport is the pipeline, and because of the characteristics of the oil itself, leading to the high quality requirements of the pipeline. While fiber laser cutting machine can achieve the pipes multi-angle precision processing to fulfil the oil transportation requirement. Professional tube fiber laser cutting machine—LF60M is used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube Φ20 * 20- Φ150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube.

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone