Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

Vmadelaser : Best Fiber Laser Cutter for Sale | Fiber Laser .

Fiber laser machines allow you to safely cut a range of metal materials with high speed and accuracy.

Find the Right Laser Cutting Machine Manufacturer in China. High Quality Laser Cutting Machine with Competitive Price.

Metal plates fiber laser cutting machine is the newest development in laser cutting. It reduces consumption, maintenance and increases speed and quality. These are the benefits of the fiber cutting laser. Metal plates fiber laser cutting machine allows clean and fast cuts with high precision. It has a very high productivity, with systems for cutting large areas of Metal Plates.

1. Low energy consumption: The power consumption of the metal plates fiber laser cutting machine is only 20-30% of that of similar CO2 laser cutting machines. The increased electrical efficiency of fiber laser greatly reduces the power consumption of the fiber laser system, saving electricity costs and reducing the initial investment in electrical equipment.

2. Fast speed: the maximum cutting speed can reach 80 m/min.

3. Easy to load and unload: Open design for easy loading and unloading.

4. Maintenance-free: 100,000 hours of service life, basically maintenance-free. No laser gas is required. The laser beam quality remains stable over time and is immediately available at startup.

VLF1530L metal plates fiber laser cutting machine is specialized in sheet metal processing, hardware, kitchen utensils, electronics, auto parts, advertising, crafts, lighting, decoration, glasses, elevator boards, furniture, medical equipment, fitness equipment, oil exploration, display stands, agriculture and forestry machinery, Processing of food machinery, bridges, ships, aerospace, structural parts, etc.

VLF1530L metal plates fiber laser cutting machine as one classic model, widely used in many common areas of our life, Used for cutting a variety of metal plates,

mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

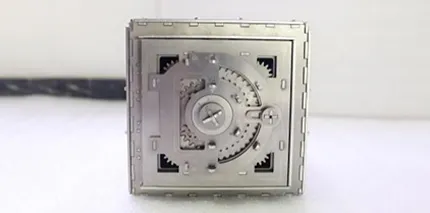

Auto Focus Laser Cutting Head

-Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

-Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

-Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Independent Control Cabinet

-Dust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolongthe lifespan of the electrical components.

-Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

Plate Welding Heavy Work Bed

-The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

-High strength, stability, tensile strength, ensuring 20 years of use without distortion;Thickness of rectangular pipe wall is 10mm and weights 4500 kg.

The Fourth Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Technical Parameters

| Machine model | VLF1530L |

| Laser power | 500W 750W 1000W 2000W 3000W(Optional) |

| Dimensions | 3000* 1500*1860mm |

| Working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 80m/min |

| Max. acceleration | 1.0G |

| Voltage and frequency | 380V 50Hz/60Hz/60A |

Do you want more detailed information? Download our catalog

Application Industry

VLF1530L Metal Plates Fiber Laser Cutting Machine as one classic model, widely used in many common areas of our life, such as processing of stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people's daily life. Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone