Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone

Staying competitive today requires cost reductions, efficiency gains and repeatable part quality that cannot be met by traditional techniques that rely on increasingly scarce, highly-skilled craftsmen. Enabled by unprecedented no-maintenance, high-reliability and low-cost IPG fiber lasers, laser welding systems have become the preferred welding solution for the manufacturing industry.

Improve your welding productivity and precision - Contact a local IPG laser welding engineer to learn how.

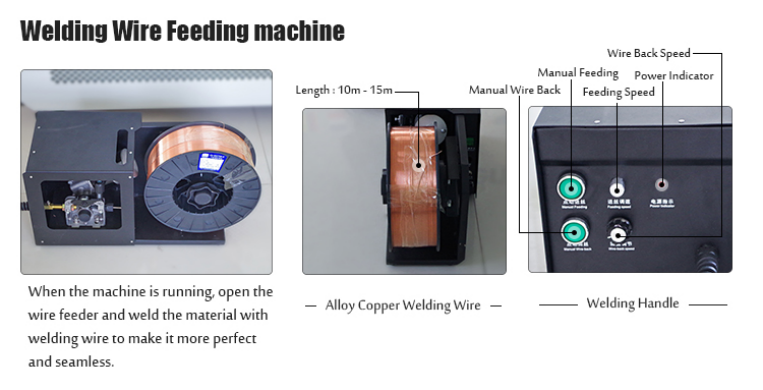

Four types copper nozzle

Support wire material:Carbon steel, stainless steel, aluminium, brass etc. Support wire diameter: 0.8mm, 1.0mm,1.2mm

Laser Source :Raycus or IPG

Lower power consumption, high photoelectric conversion efficiency. Better Beam quality than YAG laser ,Maintenance-free. 100,000 hours service life

Chiller

Brand: Hanli chiller come in a compact cabinet , save too much space,adopts special fiber laser welding head,with good cooling system

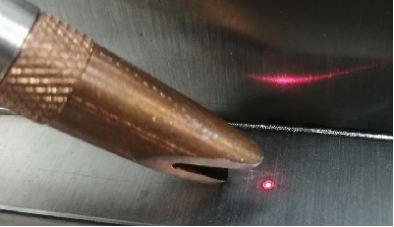

Fifth core advantage—Visable red pointing for easy locating

Visibility is really good, the red spot is coincided with the welding joint, what you see is what you get

Auxiliary Gas

Argon or nitrogen both ok. It is recommended to use argon for welding and nitrogen for cutting

Features

1. Humanized operation interface, simple intuitive operation, easy to understand and powerful.

2.The beam quality is good, the electro-optical conversion efficiency of the fiber laser is high, up to 40%, and the energy consumption is very low.

3. The whole machine has stable performance and long life, basically achieving maintenance free.

4.High aspect ratio, small weld width, small heat affected zone, small deformation and fast welding speed.

Applied Materials:

Suitable for welding many metals, such as stainless steel ,mild steel, aluminium, galvanized sheet, copper and so on.

Vmadelaser : Best Laser Welder for Sale

Find the Right Laser Welding Machine Manufacturer in China.

High Quality Laser Welding Machine with Competitive Price. Source Laser Welding Machine from China Now!

Our Newsletter

+86 531 8897 1992

Floor 3, Boko Group Headquarters, No.9 Gangxing Road, Jinan District, China (Shandong) Pilot Free Trade Zone